Offshore Wind and Aquaculture: Ntsoane presents at Intl. Partnering Forum

"So, at Kelson, we’ve found that we can create value for both aquaculture and ocean renewable energy by using cutting-edge model-based engineering techniques to develop and de-risk innovative technologies to create robust, economical design solutions to complex ocean engineering challenges. "

Full Transcript

Offshore Wind and Aquaculture: Commonalities in the Engineering Supply Chain

Hello everyone, my name is William Ntsoane and I’m a mechanical engineer at Kelson Marine Co, out of Portland, Maine. What I love about my job is getting to dive into solving some of the ocean’s most challenging problem.

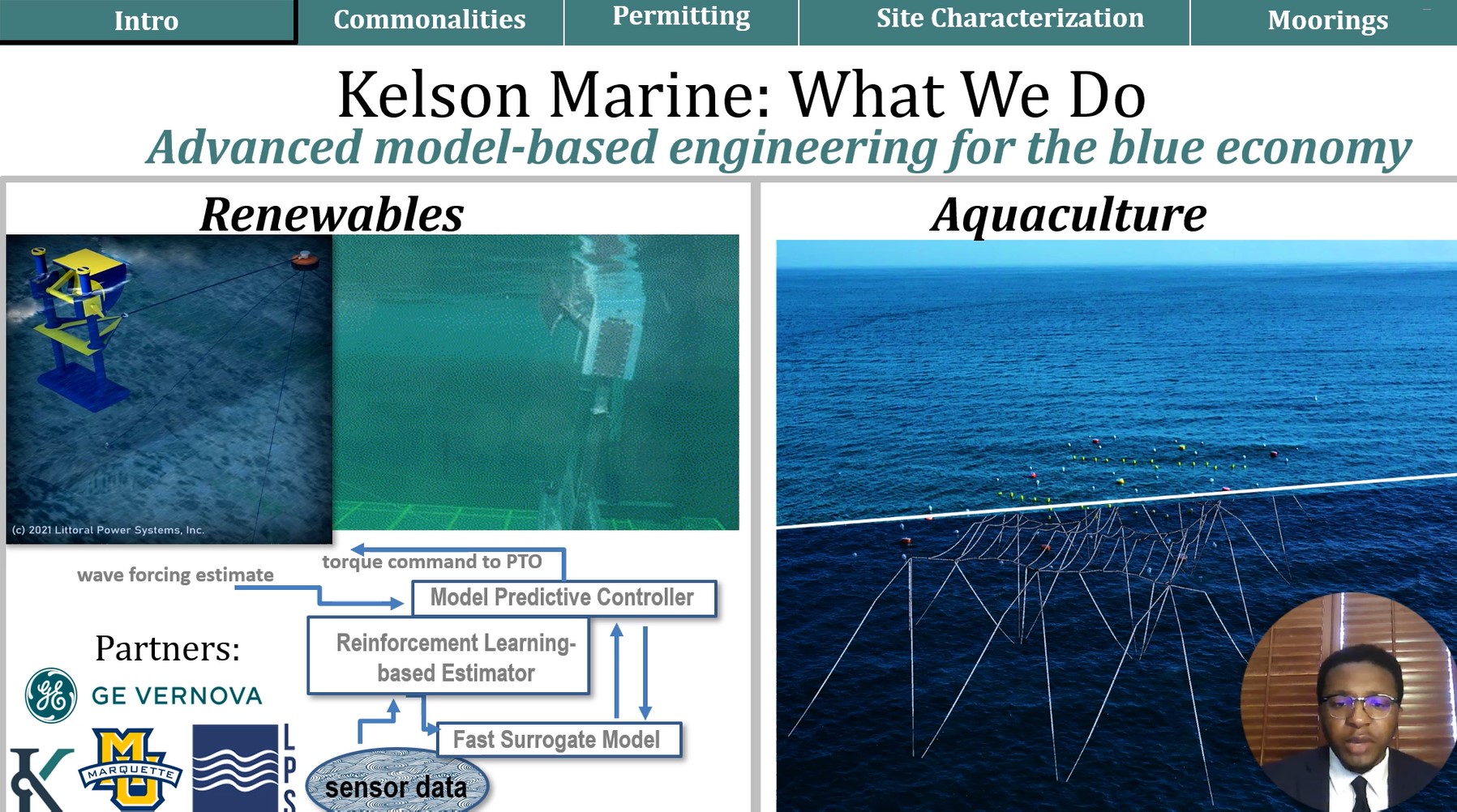

At Kelson, we are engineers who set out to minimize risk for farmers, developers, investors, and anyone who works in the ocean. Our mission is to bring advanced model-based engineering to ensure viability for blue economy stakeholders by helping them reduce risks while lowering expenditures.

We have helped partners deploy advanced ocean renewable energy and aquaculture technologies from New Zealand to Norway. This work leverages years of research and technology development funded by the US Dept. of Energy, and other national and international agencies, as well as years of commercial projects. Our work covers everything from this project developing a novel multi-body wave energy converter in partnership with GE, Marquette, and LPS, where the model-predictive control is powered by a reinforcement learning algorithm, to aquaculture arrays that we've helped develop, de-risk, and deploy for cost-effective production in exposed sites, like this experimental composites-based array for seaweed cultivation that we tested in the Gulf of Maine. We also do ASV seakeeping and optimization, heavy lift analyses, floating solar… all kinds of challenging dynamic problems in the blue economy.

We apply cutting-edge model-based engineering techniques to develop and de-risk innovative technologies and robust, economical design solutions to complex ocean engineering challenges. We work with renewable energy developers and entrepreneurs, aquaculture farmers and scientists, and research institutions.

The engineering portion of the supply chain has a lot in common with that of offshore wind projects. Every ocean engineering project starts with identifying requirements in terms of survival, performance, spatial constraints, ease of operations, and economic metrics, etcetera.

We rigorously quantify the metocean data into a risk framework, then use validated physics-based models along with a large database of marine materials properties to evaluate the performance of the structure so that we can deliver detailed array designs and optimize existing designs for economic metrics such as capital or operational expenditures.

Both aquaculture and wind are exhibiting steep increases in production capacity to meet a heightened demand for food and energy worldwide. Further maximizing production and harvest capacity will have the effect of making such products more cost-competitive. Interestingly, this exponential growth in aquaculture closely matches that of the offshore wind industry’s increasing growth in capacity. These industries will mature and grow together.

Let’s examine these commonalities in more detail, starting with CapEx cost profiles. According to NREL projections, 35% of the capital cost for a floating wind project is consumed by substructure and foundation and assembly and installation. According to some of our work with UMaine, vessels and anchor installation comprise approx. 26% of the cost of production for a large seaweed farm designed for co-location. Both industries must attain permits and social license, fund site selection and metocean studies, and we must bear the costs of mooring and installation.

Whether or not actual co-location is desirable or economical in a given situation, the overlap in the engineering supply chain between industries will help both aquaculture and wind project get in the water.

Shouldering these responsibilities together instead of separately could benefit both our parties.

Both aquaculture and ocean renewables face significant challenges in obtaining regulatory and social license. How do we address that?

• Off course, we work with ABS, DNV and other marine standards to ensure safety for those who work on and around farms, and structural integrity.

Proper array design, from spatial layout to materials selection, ensures that these systems are designed to not just survive, but perform optimally over their lifetime, and can help address social concerns about navigability, viewscape impacts, ghost gear, chances of marine mammal entanglements.

A critical step in proper design of these arrays is rigorously quantifying the design conditions for any given site. In the ocean, we have lots of processes happening simultaneously, and to accurately quantify risks it is crucial for both industries to understand interplay between variables. There’s been almost a hundred years of research on extreme value analysis, but we’re still finding new techniques to reduce uncertainty and simultaneously drive down risks and costs. For example, in a recent research project aimed at colocation, we take time series of measured wave height, period, and current velocity. And where we would traditionally extrapolate each of these variables to their extreme values and then combine 10- and 50- values, we applied a contour-based approach to quantify the actual probability of various combinations of sea states, and found that the critical survival loadcases specified by the standards are well outside of the actual 50-year contour. i.e. assuming high waves when wind speeds are high, when in actuality they don't occur at the same time). Now, these interactions are complex, so to make all this more accessible to stakeholders…

The Kelson team has worked with the International Council for the Exploration of the Seas, to take the complex interaction of currents, waves, and water depth that drive the forces on floating arrays, and distill that all into a single number we call and exposure index. We’re working on publishing this, and of all 6 candidate indices considered, our favorite is Specific Exposure Energy, a measure of the energy per unit mass of water that combines both steady current and wave motions. We like that indicator because its energy is also proportional to fluid drag on structures.

We then used this new index to examine the exposure energy of sites in the German Bight of the North Sea, currently considered for collocating seaweed and shellfish farming with wind parks.

What we found was fascinating. Here, we plot the 50-year Specific Exposure Energy; it conveniently makes a scale that goes from zero to ~10. Intuitively, behind the barrier islands, more sheltered sites are exposed to less hydrodynamic energy. But, most interesting to us is how the sites with the highest exposure energy are those that are just off the coast, where large waves entering shallow water create large fluid particle velocities, and constrictions near the coast create strong tidal and storm-driven currents. So we need to decouple the term “offshore aquaculture” into separate metrics—distance from shore, and exposure.

Now, let’s look at how we can use all of this precision in the engineering process, to keep costs in check for moorings and foundation. Take for example, a project funding by the Dept. of Energy in which we were testing a novel aquaculture array with multi-line shared anchoring and composite lines. We started with wind, wave, and current data as per usual and translated the data into design loadcases. Conventional risk management practice, when sizing anchors, is to calculate design loads based on these annualized loadcase in combination with peak biomass. But we found that thes conservative assumptions were costing the developer were almost doubling the anchoring and installation costs unnecessarily. In this project, we had the right data to calculate the maximum expected storm for each month of the year and combine that with seasonal growth data to evaluate the actual extreme loads the farm will experience. It turns out the required anchor is almost 50% lower than we would have specified if we had assumed maximum biomass with the worst-case storms.

In another example, we’ve teamed up with UMaine and UNH to evaluate the techno-economics of large-scale seaweed farming at offshore wind sites for marine CDR. We’re looking at over 60 different design and operational inputs to optimize the levelized cost of carbon from this operation. Take, for example, the farm aspect ratio. As the aspect ratio increases, so does the amount of growline available; that said, farms with greater aspect ratios also experience higher loads. So we see on the right that the capital expenditure costs for higher aspect ratios were higher, but when the cost is normalized by biomass produced, the highest aspect ratio actually leads to lower levelized costs.

Now—can you trust any of these numbers? Well don’t just make models: we validate them. And due to the nonlinear character of hydrodynamics we do all these comparisons, against real-world measurements on full-scale systems in the ocean. Because of that, we have significant confidence in the answers we’re providing to the offshore renewables and aquaculture industries. ]

So, at Kelson, we’ve found that we can create value for both aquaculture and ocean renewable energy by using cutting-edge model-based engineering techniques to develop and de-risk innovative technologies to create robust, economical design solutions to complex ocean engineering challenges. The industries of offshore wind and aquaculture have massive potential; the world is our oyster. These industries face similar challenges, and have much to learn from one another. If you have questions on how certainty in a farm design, assurance for regulators and investors, or realistic technoeconomics can help humans use the oceans for good.

Watch the Video

Kelson at the International Partnering Forum for Offshore Wind

Kelson engineer William Ntsoane served on a panel and gave a talk on on commonalities between open-ocean aquaculture and offshore wind on a panel called "The Original Offshore Farm: Aquaculture Opportunities and Emerging Technologies" alongside Benjamin A. Brown, Christoffer Valstad, and David Capotosto.