Journal Article: Quantifying Kelp Farming Costs and Reduction Opportunities

Researchers from Kelson Marine in Portland, Maine, the University of Maine, UNH, WHOI, and Vertical Bay developed a new tool that provides detailed economic analyses for kelp farmers and reveals strategies for reducing the cost of farmed seaweed. It accounts for differences in site selection, weather, crop size, and dozens of other scenario-specific factors.

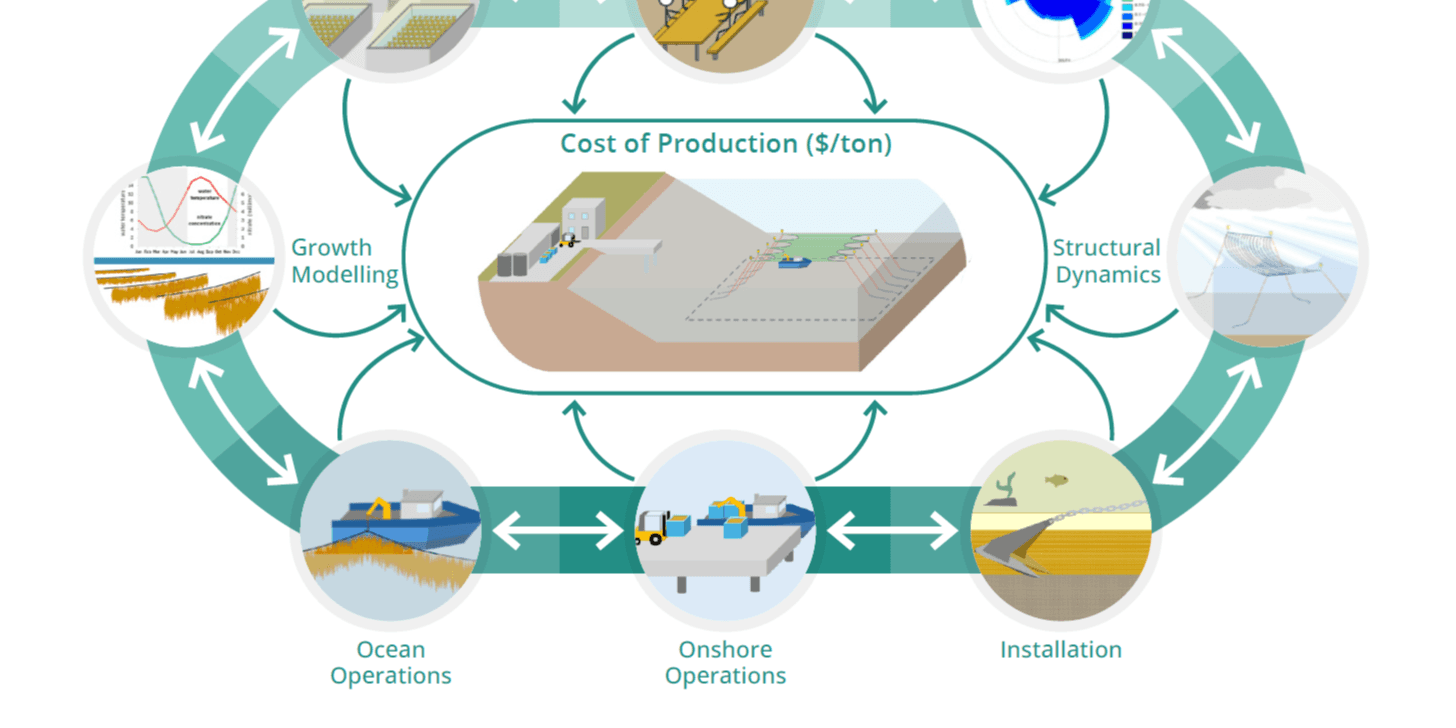

In a new peer-reviewed article in the Journal of Algal Research, Moscicki and colleagues present a techno‑economic model for large-scale kelp farming. Applying the model to a 100 m deep, 405 ha site 20 km offshore, they estimate baseline production costs of $2,618 per tonne of fresh kelp. The investigation quantified the way that the cost of farmed seaweed depends on yield, operations, and structural inputs. By redesigning structures and operations, the model reduces costs by 85% to $383 per tonne.

.

By using this tool to investigate the comprehensive implications of any given farm design or operational decision, we can help kelp farmers meaningfully reduce production costs and achieve economic sustainability.

Key findings

Cost reduction potential

In the baseline scenario, using currently available equipment and practices, the model estimates a cost of production (COP) of $2,618 per fresh tonne. By redesigning the farm structure and vessel operations – including purpose-built vessels, mechanized harvesting and processing, on-board biomass storage and cultivation at depths optimized for light availability – the COP drops by about 85 % to $383 per tonne. Sensitivity analyses show the baseline scenario is most affected by wave-height limits, vessel cruising speed, yield and distance to port, whereas the improved scenario is dominated by yield, component lifespan and structural costs. The authors stress that no single innovation drives the cost reductions; rather, integrated structural and operational improvements are needed.

- $2,618 / tonBaseline production cost

- $383 / tonOptimized production cost

Optimization

The baseline farm design uses a 1.44 km by 0.14 km array with header, transverse and cultivation lines anchored at 100 m depth. The improved design for this site reduces header length to 805 m and widens the array to 234 m, simplifying structure and installation while maintaining cultivation lines.

.

.

Why this matters

Large-scale kelp farming could diversify food production and provide low-carbon feedstocks. However, economic uncertainty at high-energy offshore sites has limited investment. This study demonstrates that a comprehensive techno-economic approach can identify design drivers and cost-savings opportunities. By modeling the interactions among structure design, farm operations and biological growth, the authors provide actionable insights for developers, regulators and investors considering offshore kelp projects.

As a seaweed farmer, this paper genuinely gave me confidence in where the industry is heading. What stood out for me was the systematic engineering approach the authors take, using assumptions that feel well-grounded and closely aligned with realistic steps I can take today. It shows that well designed cultivation systems can be optimised and scaled cost effectively, to production levels that are comparable with the costs of harvesting natural populations of seaweed.

Read the full paper

The paper is available on the Kelson Marine website and the Journal of Algal Research.